SENSHA CRYSTAL HYBRID 2K CERAMIC COATING set (Recommended use: 30 ml per car)

Product ID : 966-set

SENSHA CRYSTAL HYBRID 2K CERAMIC COATING is a revolutionary 4-liquid, 2-layer coating system—an industry first.Conventional single-liquid coatings face a trade-off: improving adhesion weakens water repellency and anti-fouling, and vice versa.

This new 2K system solves that problem by separating functions:

Base Coat: Provides powerful adhesion to the vehicle surface

Top Coat: Delivers exceptional water repellency and dirt resistance

By allowing each layer to specialize, both bonding strength and surface performance reach new heights, resulting in a crystal-clear, highly hydrophobic finish.

Contents

Contents

・ SENSHA CRYSTAL HYBRID 2K CERAMIC COATING Top Coat A (Main Component) 26ml

・ SENSHA CRYSTAL HYBRID 2K CERAMIC COATING Top Coat B (Activator) 4ml

・ SENSHA CRYSTAL HYBRID 2K CERAMIC COATING Base Coat A (Main Component) 26ml

・ SENSHA CRYSTAL HYBRID 2K CERAMIC COATING Base Coat B (Activator) 4ml

・ Funnel ×2

・ COATING CLOTH 100mm×200mm ×4

・ BASIC CLOTH Yellow L size 400mm×400mm ×2

・ COATING SPONGE 90mm×20mm×30mm ×2

・ Instruction manual

-

International12,680 YenNo.

Added to Cart

* You can order either domestic or international products, but not both.

| Origin | Japan |

| List Price | 12,680 Yen |

| No of Use | 1 |

| Cost per car | 12,680 Yen |

SENSHA CRYSTAL HYBRID 2K CERAMIC COATING

Durability: Up to 8 Years

Innovative Multi-Layer Design for Superior Protection

The 2K CERAMIC COATING represents a new generation of professional-grade coating technology, developed through a completely new approach ― a 4-liquid, 2-layer structure.

This design resolves the trade-off between adhesion strength and hydrophobic / anti-stain performance, long a limitation of single-liquid coatings.

Separation of Functions for Optimal Performance

In conventional coatings, achieving both strong adhesion and excellent water-repellency is difficult within a single liquid.

The 2K system separates these into two layers, each optimized for its role.

Base Coat:Bonds firmly to the paint surface while chemically fusing with the Top Coat layer, ensuring high adhesion and durability.

Top Coat :Maximizes hydrophobicity, gloss, and anti-stain performance by relying on the strong anchoring of the Base Coat. It creates an ultra-smooth, mirror-like surface at the nano level.

The result is an exceptionally deep, transparent gloss and long-lasting protection that conventional coatings cannot achieve.

Advanced Materials: Polysilazane × Nano Carbon

The hybrid formula combines polysilazane for superior hydrophobic performance (contact angle 102°) with nano carbon additives for enhanced water-sliding and anti-static effects.

This separation provides advantages in freshness, consistency, and long-term stability.

Self-Leveling Gloss Finish

The coating film has a self-leveling property that visually corrects fine scratches and enhances surface depth, creating a luxurious, reflective shine.

Why Four Liquids?

Although the coating system is 2-layered (Base + Top), it consists of four liquids (A/B + A/B) ― each divided into Main Agent (A) and Activator (B).

This separation provides distinct advantages in terms of freshness, consistency, and long-term stability.

Always Fresh on Application

Mixing A and B immediately before use ensures a freshly activated coating with full chemical reactivity.

Stable Curing Process

Once mixed, curing begins in a controlled manner, unaffected by ambient temperature or humidity.

Excellent Shelf Stability

When unopened and stored properly, each component maintains quality for up to one year.

Comparison with Conventional Single-Liquid Coatings

Simply layering single-liquid coatings provides only limited benefits:

Risk of Dissolving the Underlying Layer

Most hard-type coatings are solvent-based.

When applying a second or third layer, the solvent can partially dissolve the previous layer, effectively eliminating the intended layering effect.

Allowing sufficient curing time can reduce this, but since the cured film is only about 0.2?0.3 μm thick, even slight dissolution renders layering benefit nearly zero.

No Improvement in Adhesion or Hydrophobic Performance

Applying the same coating multiple times does not enhance chemical bonding strength.

Because the coating liquid is identical, there is no improvement in adhesion or water repellency ― the performance remains essentially unchanged.

Risk of Reduced Transparency

As the film becomes thicker through repeated applications, transparency declines beyond a point.

Since coating materials are not perfectly transparent substances, excessive layering may actually dull the gloss and clarity rather than enhance it.

In conclusion, the 4-liquid / 2-layer structure is not merely formal.

It is a deliberate design that optimizes chemical reaction, stability, and finish quality all at once.

The 2K CERAMIC COATING system embodies this ideal ― a true next-generation coating technology engineered for professional results.

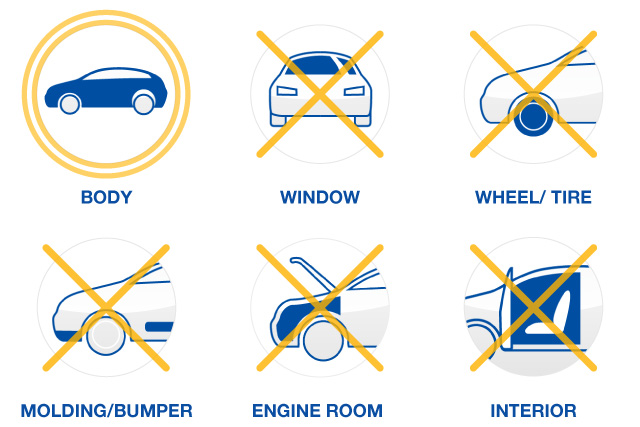

Suitable for Wheels

Thanks to its excellent heat resistance, 2K CERAMIC COATING is also highly effective for wheel surfaces, preventing brake-dust adhesion and simplifying cleaning.

Package Contents

| COMPLETE KIT (1 Vehicle) Contents ・Top Coat A (Main Component) 26ml ・Top Coat B (Activator) 4ml ・Base Coat A (Main Component) 26ml ・Base Coat B (Activator) 4ml ・Funnel ×2 ・COATING CLOTH ×4 ・BASIC CLOTH Yellow L size ×2 ・COATING SPONGE ×2 ・Instruction manual |

PRO BOTTLE SET (1 Vehicle) Contents ・Top Coat A (Main Component) 26ml ・Top Coat B (Activator) 4ml ・Base Coat A (Main Component) 26ml ・Base Coat B (Activator) 4ml ・Funnel ×2 ・Instruction manual |

Application Procedure

1. Prepare the surface using BODY CLEAN or WAX OFF, and allow to dry completely.

2. Mix Base Coat A with B. Apply evenly using a coating sponge, then immediately wipe off with the Basic Cloth.

3. After finishing the Base Coat, mix and apply Top Coat A + B using the same method.

4. Ensure there is no residue left before curing.

Recommended wipe-off time (depending on temperature):

・ 35°C : 2 - 3 min

・ 25°C : 4 - 5 min

・ 10°C : 6 - 7 min

Do not delay wiping off ― excess drying may cause difficulty in removal.

Key Features

・ 4-Component / 2-Layer Architecture for optimal performance

・ Polysilazane + Nano Carbon for advanced hydrophobic and anti-static protection

・ Deep, mirror-like gloss with self-leveling properties

・ Long-lasting durability and resistance to dirt adhesion

・ Designed for professional use and consistent results

Global Track Record

SENSHA products are trusted in over 34 countries worldwide, with approximately 800 authorized professional locations across Asia, Europe, the Middle East, and Africa.

In Japan, our coatings are widely used by car wash specialists, service stations, and automotive professionals.