Syncshield PRE-CUT PROTECTION FILM for Bicycle Crank Arms DURA-ACE R9200 SHIMANO 1 pair (Recommended use: 1 piece per car)

Product ID : 131

Thermoplastic polyurethane (TPU) paint protection film (PPF) , 150μm thickness, 5-year durability. Self-healing fluorine coating layer. Ultra-transparent acrylic adhesive. Effects: Surface protection, Discoloration prevention, Scratch resistance, Self-recovery, Anti-fouling, Water repellency, Oil repellency.Contents

・ Syncshield PRE-CUT PROTECTION FILM for Bicycle Crank Arms DURA-ACE R9200 SHIMANO 1 pair

・ Instruction manual

-

International4,800 YenNo.

Added to Cart

* You can order either domestic or international products, but not both.

| Origin | Japan |

| List Price | 4,800 Yen |

| No of Use | 1 |

| Cost per car | 4,800 Yen |

Syncshield for Cranks (9200 DURA-ACE)

About PPF

PPF (Paint Protection Film) has been installed mainly for the purpose of protecting the surface of automobiles, preventing discoloration, and preventing scratches.

This product Syncshield is a PPF (paint protection film) jointly developed by several Japanese film-related manufacturers and SENSHA as a new flagship product of the SENSHA brand. It is a very reliable product currently used in about 800 stores in 34 countries all over the world.

Material

The material used for the Syncshield is TPU (thermoplastic polyurethane). This material has excellent weather resistance, elasticity and flexibility.

Scratch Resistant Performance

The strong 150μm polyurethane film protects your bicycle from external damage such as scratches and rubbing.

Fading Prevention Performance

Not only the polyurethane film, but also the coating layer and adhesive layer have the ability to block UV rays and protect your bicycle from fading.

Self-healing Performance

Since the Syncshield has the function of self-healing the film itself, it is possible to almost prevent the occurrence of small scratches. If it is a slight scratch such as a slight rubbing, it will repair itself.

Antifouling performance

The coating layer applied to the surface of the polyurethane film has the effect of preventing the sticking of mud and dirt that adheres daily.

Water repellency

Syncshield has excellent water repellency. The result of water contact angle test was 110°

Transparency

It has been developed with a high degree of transparency so as not to spoil the color texture of the bicycle itself. Even after the application, you won't notice that the film is glued on

Non-yellowing performance

The Syncshield uses a special urethane material that does not yellow. There is no obvious yellowing like general urethane materials.

Flexibility

It was developed to follow complicated cubic curved surfaces without difficulty. Achieves high workability.

Set contents and application location

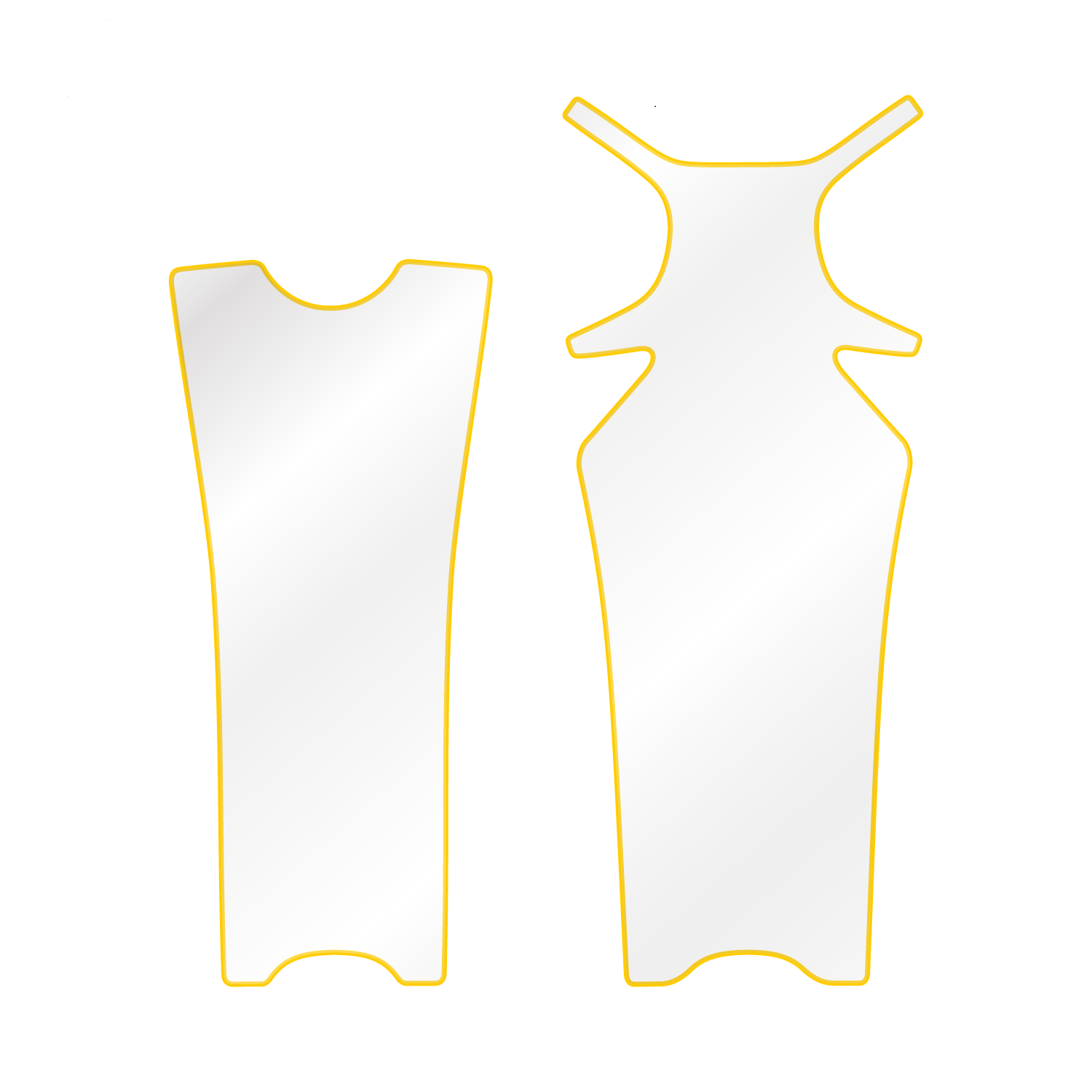

The set contents of this product are [for 9200 Dura-Ace ... 2 pieces (1 piece each for right crank and left crank)

Please use it to prevent scratches on the crank surface.

Also used in all SENSHA Bicycle shops - the bicycle washing specialist.

At each SENSHA Bicycle store, which specializes in bicycles and coatings nationwide, we apply protection films on a daily basis. The protection film used there is this product Syncshield.

With the support of many customers, we have constructed many bicycles. Please give it a try!.

How to use

1) The Syncshield has 3 layers at the time of shipment. Peel off the protective film with the round sticker on it.

2) Firmly remove dirt and oil from the crank to be installed.

3) Spray a generous amount of our dedicated Syncshield construction liquid on the crank to be constructed.

4) Remove the Syncshield from the mount. At this time, peel off while spraying the construction liquid on the adhesive surface.

5) Attach the Syncshield peeled off from the mount according to the shape of the crank.

6) Use our rubber squeegee (hard / small) to gently drain the water from the gap between the Syncshield and the crank so that it does not shift. When the adhesive surface of the Syncshield dries, the adhesive strength increases and it sticks firmly.

※ When constructing, be sure to use the dedicated syncshield construction liquid. If you use a liquid other than the special construction liquid, we cannot guarantee the product.